Dendy Adityawarman

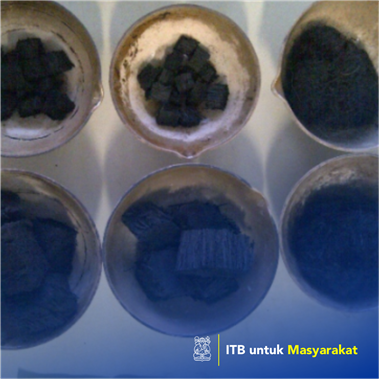

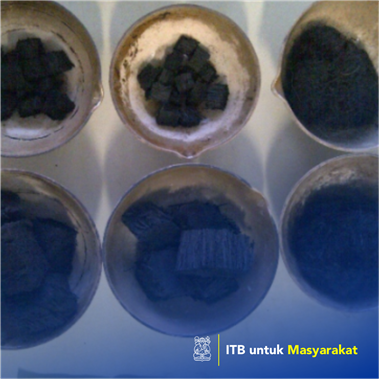

The experiment conducted by Prasetyo and Sitompul, (2016) by using the OPT used from a replantation area, Sei Bahar, 70 km to South of Jambi, Southern part of Sumatera, Indonesia. The OPT were cut into 40 cm size from a trunk and taken to Bandung for experiments. The outside part (peel), inside part, and central part were separated and cut into smaller pieces with 2 variations of dimension. This research shows the potential utilization of OPT as renewable energy resource. Furthermore, OPT biomass is highly potential as environmentally friendly fuel and make life cycle of oil palm industry near perfect for food, energy and biochemical source. Torrefaction is a promising process for processing OPT as it leads to higher heating value and improved energy quality. The process modeling of OPT drying and torrefaction gives the charcoal yield of 0.2972 compared to experiment yield of 0.24. The calorific value (HCV) of torrefied OPT with RGibbs is 6,901kcal/kg that is similar with experiment result of 6,939.22 kcal/kg.

Penerapan Karya Tulis

This research concern on upgrading tradional wood such as drying and torrefaction of oil palm trunk (OPT), abundant biomass resources coming from replantation of oil palm. The processes are very crucial in treating of OPT before utilization for energy source due to high level of water content and volatile matters in the biomass.