Pandji Prawisudha

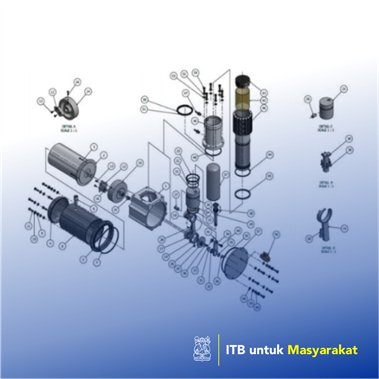

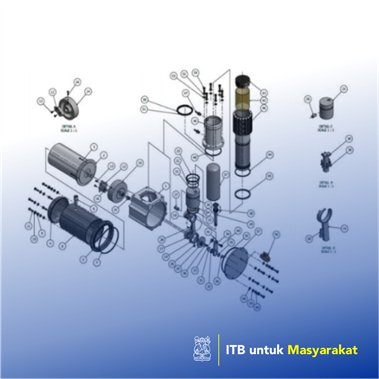

Due to the sensitivity of geometry and dimension to the engine performance, we aim to locally manufacture several components of Mo2SE, a 200-watt beta Stirling engine based on the dimensions and tolerances stated in existing design. The locally manufactured components will be assembled with the existing engine, and performance tests will be conducted. The tests will be used to evaluate the deviation of power produced by engine with locally manufactured component compared to engine that use existing component. This year, eight components will be manufactured by two different manufacturers. The first manufacturer, Politeknik Manufaktur Bandung, manufactured all the components using CNC tools and/or machining center. Few conventional machining methods only used to modify the surface/geometry into final desired specification. In the other hand, the second manufacturer, CV. Budi Mulia Mandiri, manufactured the components using only conventional machining methods.

Penerapan Teknologi Tepat Guna

Stirling cycle is considered as the most efficient power cycle. In addition, the engine utilizes external heat as energy sources, thus, has high flexibility to utilize all types of fuel. However, the performance of the engine is greatly affected by irreversibility such as friction, vibrations, and heat losses. Furthermore, it is usually difficult to design an efficient engine as a single component may affect two or more parameters of the engine. For example, the determination of the gap between power piston and cylinder interface may affect the engine in two contradictive outcomes. If the gap is too tight, we can prevent the gas from exiting the system and thus, minimizing volumetric power loss. However, a tight fit will also increase the friction at the interface and subsequently increasing the power loss due to frictional forces. Additionally, even though an optimum dimension has been determined, further deviation from the ideal Stirling cycle can be produced from non-ideality during manufacturing processes. This further limit the actual efficiency of the designed engine.