I Dewa Gede Arsa Putrawan

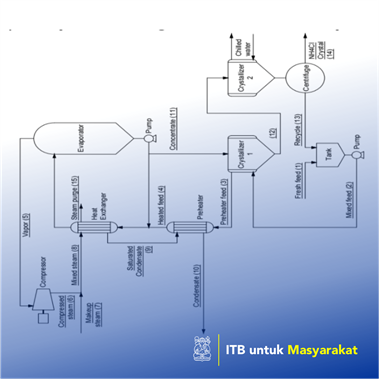

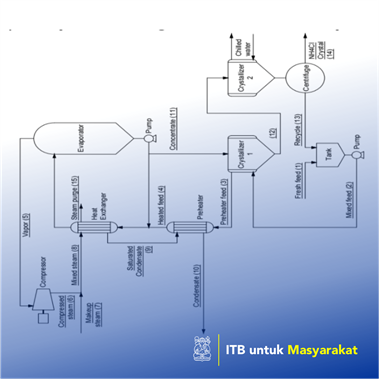

This research is aimed to develop and evaluate MVR evaporative crystallization process for recovering NH4Cl from the wastewater of organotin-based PVC thermal stabilizer plants. An MVR evaporative crystallization process was developed and the material and energy balances were derived. The process was then simulated to study the effects of process variables on the process performance. The technical parameters evaluated include compressor, heater, preheater, precrystallizer, and crystallizer specific loads as well as recycle ratio. In this paper, specific load is expressed in MJ/kg NH4Cl crystal and recycle ratio is defined as the flow rate ratio of the recycled wastewater to NH4Cl crystal. The concentration of NH4Cl in wastewater affects all of these performance indicators, except recycle ratio. Higher NH4Cl concentration means lower water content in the wastewater to be treated and less water to be evaporated and compressed. In other words, less water per weight of wastewater that has to be removed from the solution to achieve the targeted saturation in the concentrated solution. This requires less energy to drive the compressor and less heat that has to be supplied to the solution making the compressor work and heating loads decrease against NH4Cl concentration.

Penerapan Karya Tulis

Organotins have been known to be very effective in stabilizing PVC resin during thermal processing. The production of organotin-based PVC thermal stabilizers, however, results in a significant amount of hydrochloric acid that has to be neutralized using an ammonia solution and consumes a lot of water for washing the product. The production process, therefore, produces wastewater containing ammonium chloride (NH4Cl) that has to be treated to avoid environmental problems.