Indra Djodikusumo

This research is aiming to reverse Stirling Engine 200W Beta Type Product from japan. This program also under collaboration between lnstitut Teknologi Bandung and Teikyo Universfty from Japan. We also have conducted Reverse Engineering (RE) and design for Manufacture and Assembly (DFMA) analysis for the engine. In the middle of our reverse engineering analysis process, we noticed that there are several defects that may occur due to assembly/disassembly process, production defect, or operation defects. Also, we noticed several ambiguous design intent in SECOTEC components that may be a redundant and can be omitted. Afterward, our research group conducted a stack up tolerance analysis. This analysis become the most important step in Mechanical Production Engineering research this year because there are so many possibilities of assembly performance come out with several possibilities of individual part as well. The stack up tolerance analysis case assumption used in this project is a worst case tolerance consideration because we are going to fabricate the prototype, so there we should not let the sfackup failure probability at all.

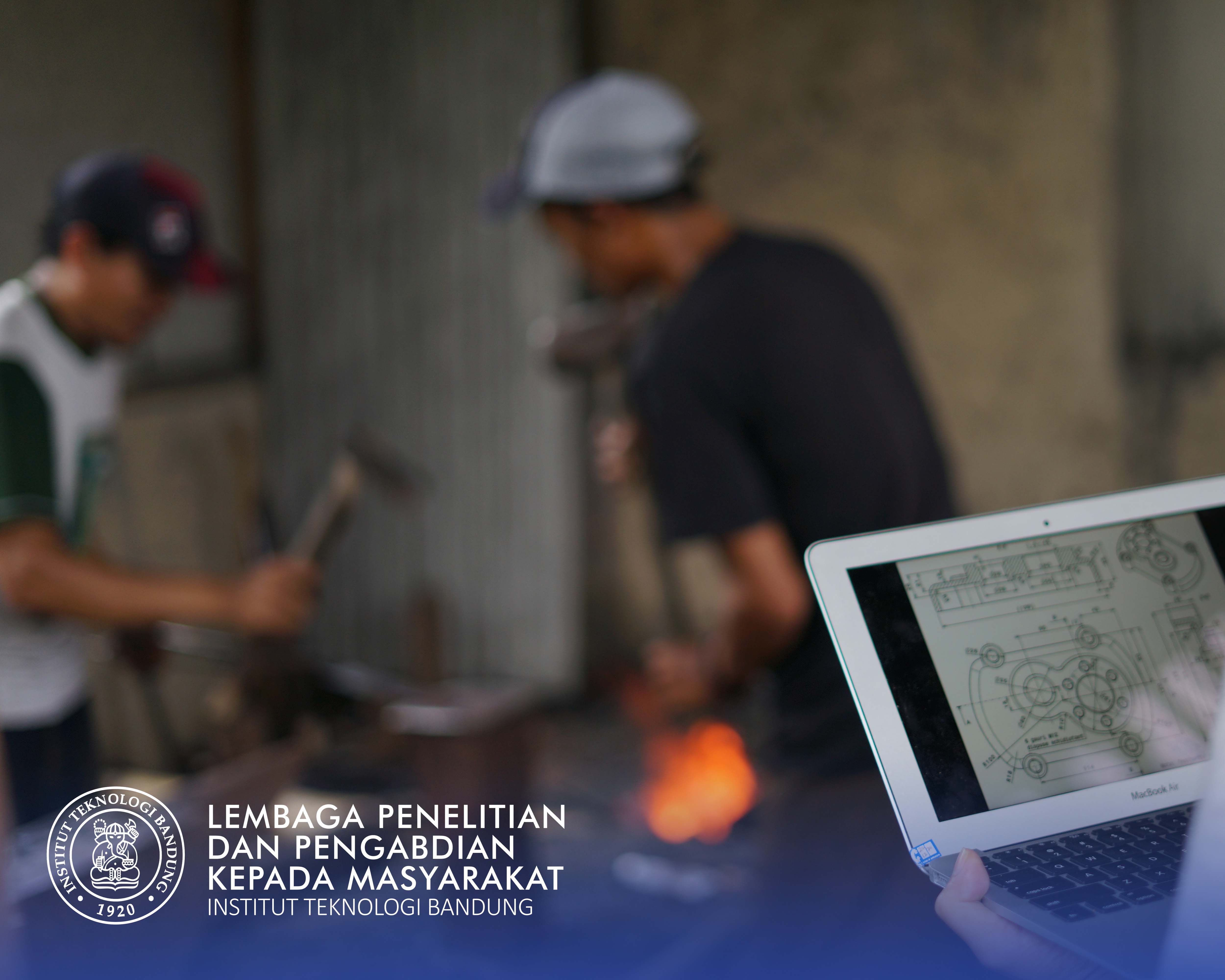

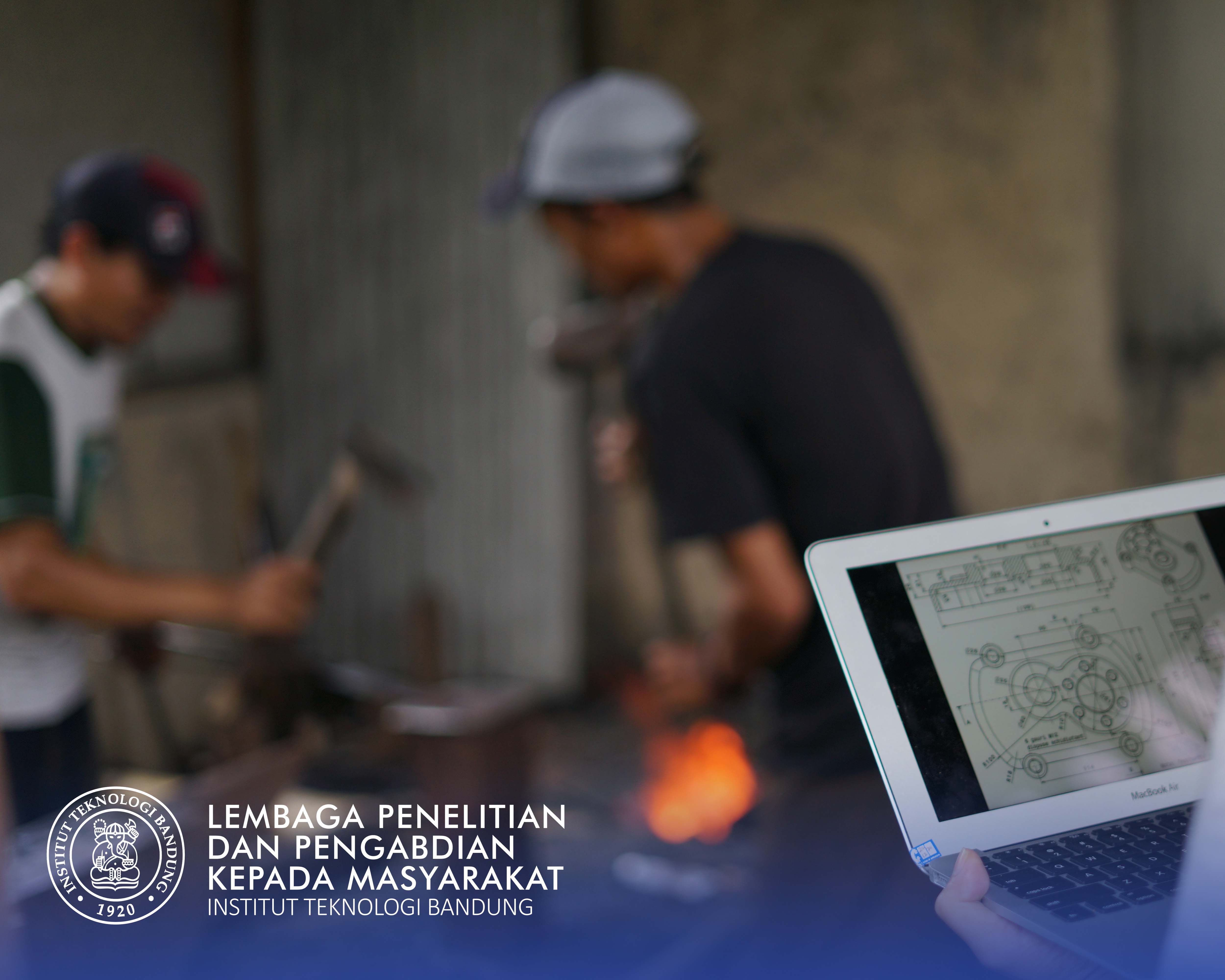

Penerapan Teknologi Tepat Guna, Penerapa Karya Seni/Desain/Arsitektur/Perencanaan Wilayah

Proses Perencanaan Produksi dan Pembuatan Mesin Stirling Tipe Beta 200 W