Natas Setiabudhi Daryono Putra

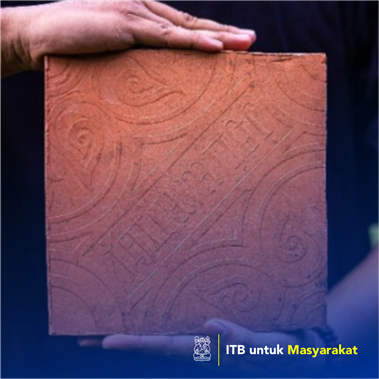

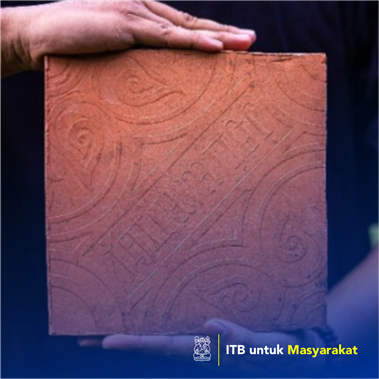

In ceramic science, the commonly used filler is shamoot or grog or quartz sand. The local people there call kareweng a filler that comes from finely ground tile waste / fragments. To strengthen it, apart from kareweng, Jatiwangi‟s clay is mixed with refractory (ceramic raw material with very high melting temperature), namely quartz, and mixed with Sukabumi clay. In addition, it is added with oxides and stains (mineral dye that has gone through the combustion process) to provide aesthetic value. Apart from formulating the body, production equipment also plays an important role in obtaining quality ceramic products and work efficiency. The prototype of the product is produced using a manual press machine so that the tiles become denser which causes the body to be more resistant to rolled up and minimizes the possibility of air pockets in the ground (causing cracks). This research is the first step to obtain a body formula that can later be used to make products other than tile. But it does not rule out, Jebor can also make custom roof tiles with this formula. In this research, clay formula processing still uses manual methods, but in the future it is expected to use the latest machines, such as ball mills filter pressed, pugmill and extruders. This machine will speed up the production process and the results will be more consistent. The output produced is floor and wall tiles with Majalengka and Cirebon decorations.

Penerapa Karya Seni/Desain/Arsitektur/Perencanaan Wilayah

Jatiwangi has been known for a long time as a center for the production of quality ceramic roof tiles that were marketed to almost all parts of Indonesia, even between the 1980s and 1990s it succeeded in penetrating the markets of Europe, Malaysia and Brunei Darussalam. Along with the times, the interest in ceramic tiles has declined to be replaced by other mediums that are considered cheaper and more practical, such as asbestos, fiber, or light metal steel. Seeing this condition, there was an idea to diversify products other than roof tiles, such as tableware or home décor products. We assume that a quality product comes from qualified materials. Jatiwangi‟s clay has some different characteristics from similar types of clay such as Plered Purwakarta clay. Jatiwangi clay is not sticky when sieved wet, making it easier to process, both for the clay body mixture or used as an engobe. Some ceramics artisans and entrepreneurs in Jatiwangi have actually made product innovations by making floor tiles or wall tiles, but they often experience failures, such as cracks in the tile body or often the tiles are curled up. From this experience we can then draw a hypothesis, that the Jatiwangi clay material does not have a filler (forming a frame).