M. Agus Kariem

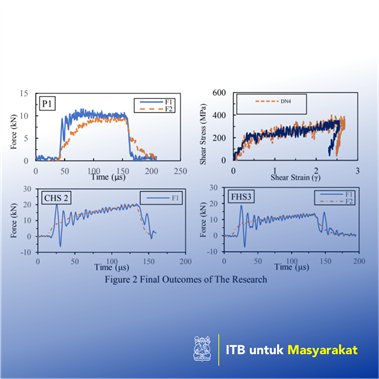

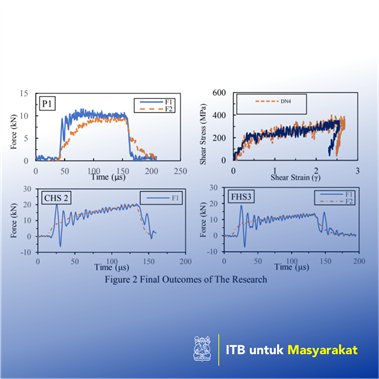

Different types of transmission bar used in split-Hopkinson shear bar (SHSB) resulted in inefficiencies in manufacturing and application of the apparatus. In this research, Author tries to design a fixture so that SHSB could be conducted with a conventional solid transmission bar. The research is conducted by using finite element analysis in Abaqus/CAE. The research successfully determined the effect of the fixture dimensions to the result of punch, double-notch, and hat-shaped techniques. Finite element analyses are conducted to study the effect of installing a fixture to both the punch and double-notch apparatuses. Validation of the finite element method is conducted experimentally and theoretically. The finite element analysis provides the strain-time curve of the apparatus which is needed to form IRT curve and true stress-true strain curve. The IRT curve and true stress-true strain curve are then compared to the IRT curve and true stress-true strain curve of the conventional SHSB punch and double-notch apparatuses to determine the effect of the modifications.

Penerapan Karya Tulis

Split-Hopkinson shear bar (SHSB) is a derivation of split-Hopkinson pressure bar which is used to acquire material responses under impact shearing load. A modified transmission bar is needed for SHSB testing which resulted in inefficiencies in manufacturing and application. In this research, Author tries to design a fixture so that SHSB punch, double-notch, and hat-shaped techniques can be conducted with a conventional transmission bar.