Yuli Sri Afrianti

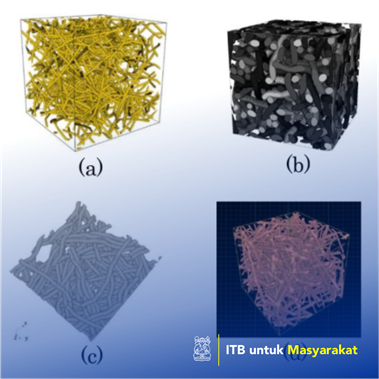

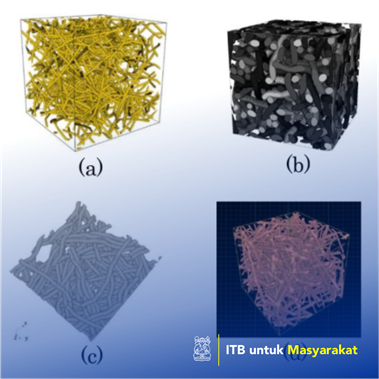

There are several fiber models, for example, the model with or without interaction. The model with interaction can give us the non-overlapping system, such as fibers packing, sedimentation, and Random Sequential Adsorption. On the other hand, an overlapping system can be obtained by the model without interaction, i.e. the Boolean model and the Poisson cylinder process (PCP). Moreover, the fibers can be modelled either as dilated curved lines [1, 2], as chains of balls [3-5] or as cylinders [6 - 8], with different cross-section, such as circle, square, and triangular. Faesel et al. [2] proposed the model for a bending fibers as dilated curves line. The realization of fiber model is shown in Figure 1(a), whereas fibers as chains of balls with the force- biased packing approach introduced by Altendorf [4]. This research focused to explain non- overlapping stochastic model of fiber with a circular cross section and the model applied to the glass fibers reinforces composite as shown in Figure 1(b). Easwaran [5] also developed fibers model as a chain of the balls, but this research focused to explain overlapping fibers, especially for bundle fibers as depicted in Figure 1(c). Fibers can also be modelled as cylinders. Schladitz et al. [7] modelled the fibers as cylinder with a circular cross-section. They made a model for non-woven fiber by Poisson lines process, dilated by a sphere with circular cross-section to optimize the acoustic properties. The realization of this model can be found in Figure 1(d). Similar to a model in [7], Vecchio [8] introduced the fibers model using the PCP with circular, square and triangle cross sections. This model is applied for cellulose pulp composites as paper.

Penerapan Karya Tulis

The application of the fiber has been spread to many fields. For example, the wood fiber can be used in building construction such as wall, roof, floor, and acoustic room. Furthermore, wall of automotive interior also made by fibrous structure. Therefore, the design process of such materials is therefore still continuously researched and developed in order to create high quality products. To avoid excessive costs, it is essential to establish a non-destructive design technique of the macroscopic material. The virtual design of fibrous material can be created as a stochastic model realization.