Steven Chandra

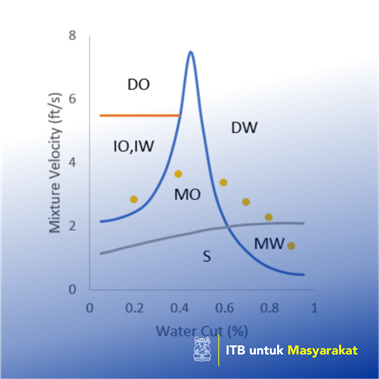

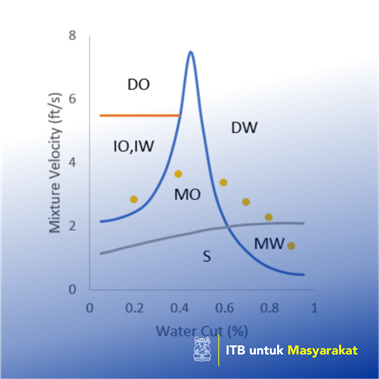

This field is characterized by extreme oil viscosity, up to 4000 cP at surface condition, which leads to high backpressure while delivering fluid to pipeline system. This viscous oil creates unstable flow, causing unfavorable flow-pattern: slug flow to annular flow. As a result, the water and oil are not coherently arrived at the same time at receiving facilities, leading to highly frequent occurrence of oil-water slug phenomenon. An idea is presented in this study to reduce the occurrence of severe slugging phenomenon by performing water blending scheme during fluid transportation. The idea is based on a hypothesis that performing forced emulsion of brine and heavy oil promotes dispersion of oil into small droplets which can be carried by injected water under relatively lower velocity. This idea is attractive since it is simple to perform, by only directing produced water from water zones below hydrocarbon bearing zone or reactivation of high water cut wells to the pipeline system. In order to increase the efficiency of forced emulsion process, it is then decided to estimate the minimum acceptable water cut to develop sufficient emulsion viscosity to prevent high backpressure. Based on simulation using commercial software, the result shows that water cut should be maintained to be more than 80%. Less water cut will lead to high backpressure which delays arrival time of oil for more than one day from water. This

Penerapan Karya Tulis

Flow assurance has been a major problem in the development of a heavy oil field. It is not common that this issue has a multiplier effect from reservoir up to processing facilities, reducing productivity and in turn, increasing financial burden. A lot of major oil and gas operators in Indonesia have spent a lot of capital dealing with managing complex reservoirs with severe flow assurance issues, namely high water cut, excessively viscous oil and its effect on fluid flow. X Field, a complex oil field in Indonesia, currently produces 3000 BOPD and the recovery factor is 4% in thirty-year production.